our products

ECOFLUX SINTERED MAGNET | 01/08

EcoFlux: Securing our electric future.

Designed and engineered using our breakthrough technology — which improves composition and microstructure — our EcoFlux magnets are sustainably produced and able to meet requirements across the entire performance range with a special emphasis on high-growth, high-temperature applications.

In short, we’re using our technology to disrupt the industry by manufacturing a superior quality product designed to exact specifications for a given application. It can be produced and delivered as block or finished pieces or supplied as assembly.

Our high-performance and sustainable EcoFlux products:

Can be produced with everything from virgin materials to 100% recycled, end-of-life feedstock materials

Requires 20% less heavy rare earth materials than traditionally produced magnetic materials using competitors’ technology

Performs at higher temperatures and in harsher environments

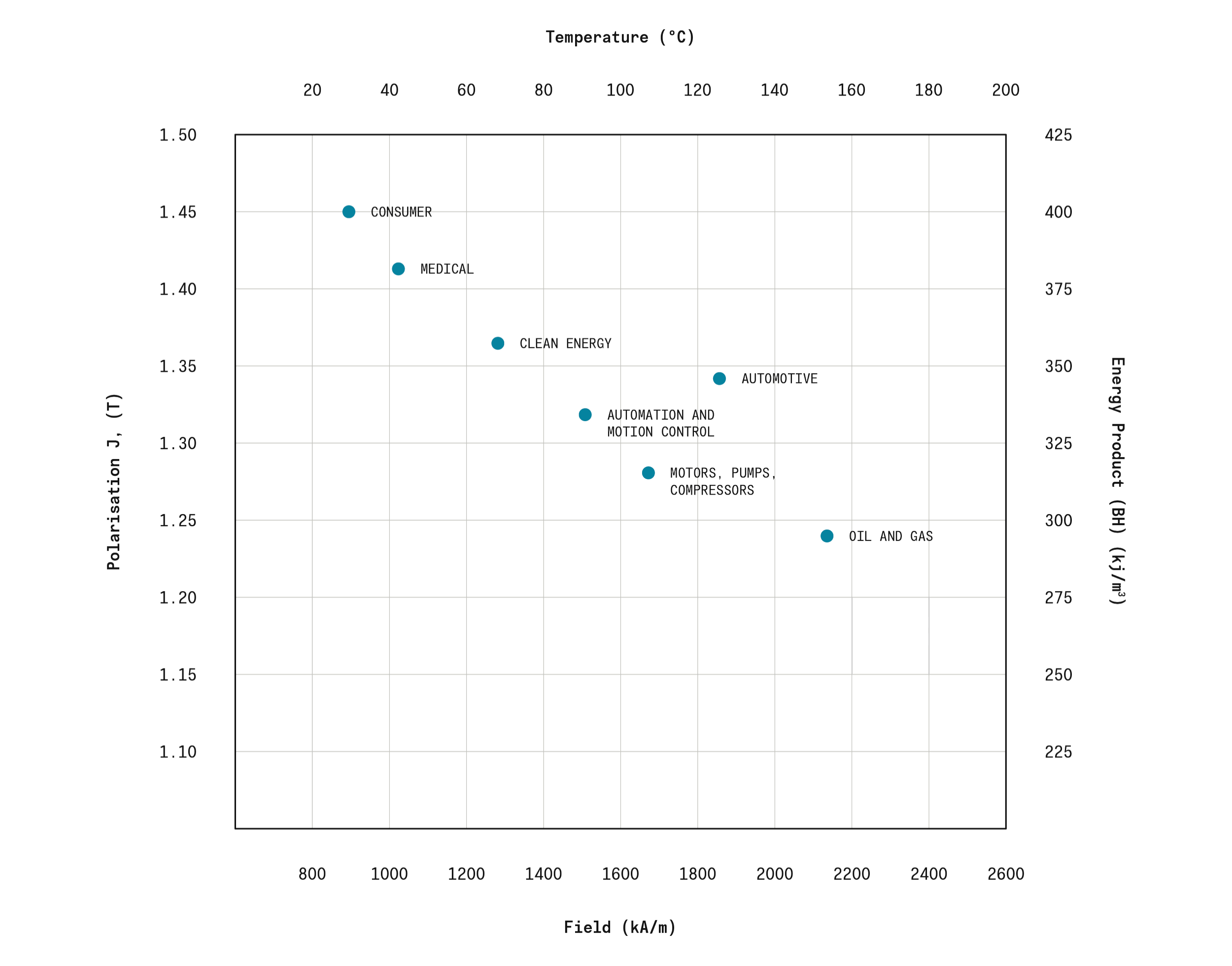

PERFORMANCE RANGE | 02/08

Incredibly powerful. Fit for all applications.

Our EcoFlux magnets can meet requirements across the entire performance range with a focus on high-temperature applications.

CHART | EF-004

EcoFlux performance range

Note:

EcoFlux meets the needs of a wide range of applications

EcoFlux excels in temperatures >100°C

EcoFlux excels in temperatures >100°C

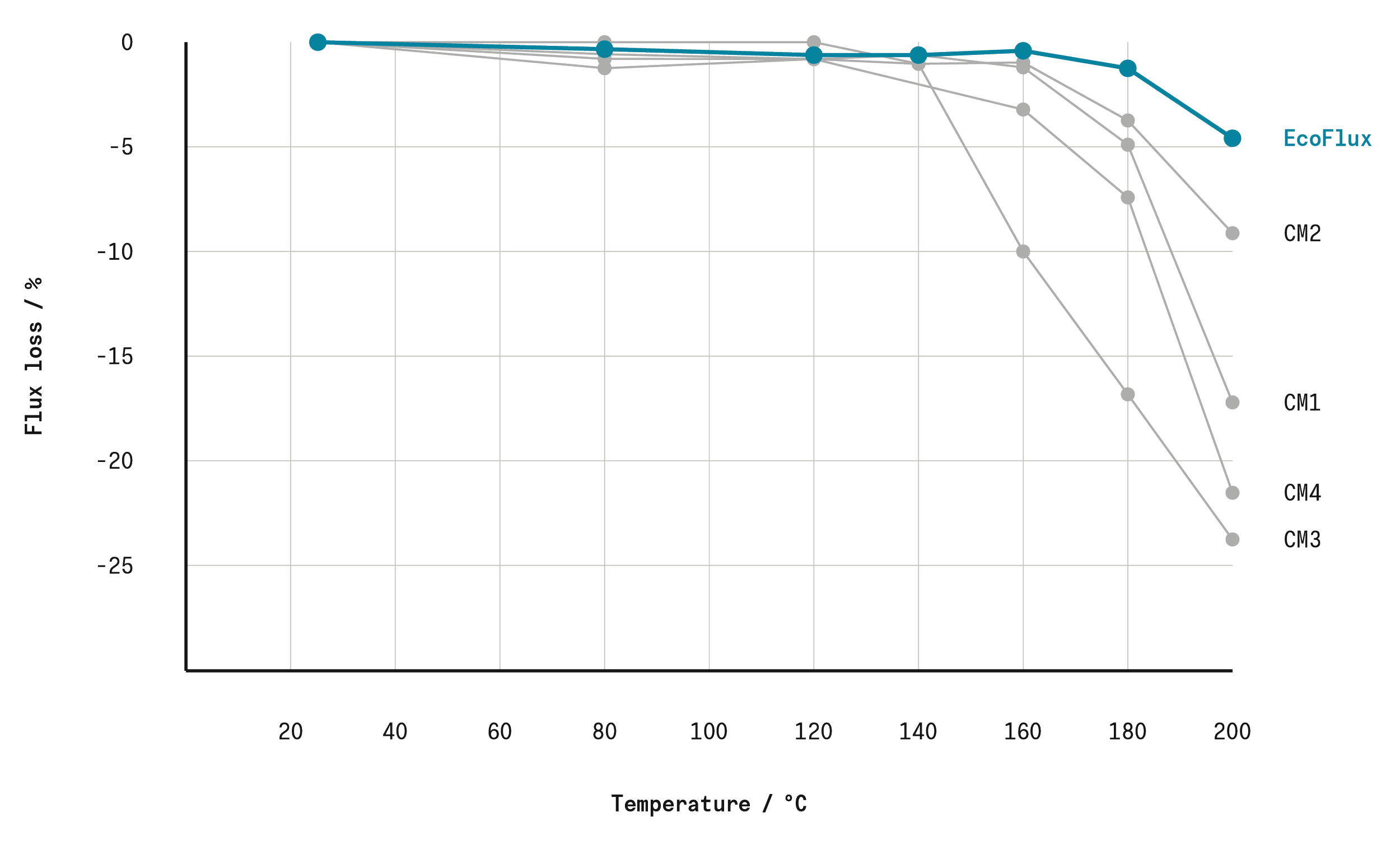

PERFORMANCE FEATURE: THERMAL STABILITY | 03/08

Built to take the heat.

Heat can greatly impact the performance of a magnet. At high temperatures, magnetic performance can be significantly reduced. In addition, when a magnet cools down after exceeding certain temperatures, its performance remains impeded for the rest of its operating life. This measure of performance at high temperatures is referred to as thermal stability. With our GBE® technology, we produce a magnet that exhibits the highest thermal stability with the least amount of heavy rare earth elements of any magnet.

CHART | EF-005

Flux aging test results on EcoFlux and other high-performance commercial magnets (CM)

Note:

EcoFlux shown to dominate in high-temperature industrial applications

Source: https://www.sciencedirect.com/science/article/abs/pii/S0959652619329610

EcoFlux magnets experience <5% irreversible losses above 180°C

Competitors’ magnets experience >20% irreversible losses above 180°C

LESS RARE EARTH ELEMENTS REQUIRED | 04/08

EcoFlux requires less heavy rare earth metals to achieve its incredibly high performance.

Less rare earths. Higher performance.

Our magnets exhibit higher magnetic flux, higher coercivity, increased resistivity and better stability while reducing the amount of heavy rare earth elements required (such as dysprosium) by at least 20%. Our process is not only extremely efficient but also provides a huge competitive advantage over traditional manufacturers.

FLEXIBILITY OF FEEDSTOCK | 05/08

More than one way to make a magnet.

Our technology gives us the flexibility to use any and all raw materials and feedstock to manufacture our high-performance magnet products. And it means we can create a superior quality magnet using 100% recycled materials.

EcoFlux magnet made from recycled end-of-life scrap material.

RESOURCE EFFICIENCY & SUSTAINABILITY | 06/08

Sustainability at every step.

Our proprietary GBE® technology enables us to produce magnets using less energy and less rare earth materials whether we use recycled or virgin inputs, resulting in a significantly reduced impact on our planet per given unit of output.

Additionally, when we apply our M2M® technology to the manufacturing process, we can produce high-performance magnets that are sustainably sourced and made from 100% recycled materials.

There are approximately 600,000 tons of end-of-life feedstock material waiting to be turned into high-performance magnets.

SECURE SUPPLY CHAIN | 07/08

A solid, dependable and decentralized supply chain.

Since our process leverages an entirely domestic source of alternative, abundant materials, we do not depend on China. This allows us to bypass supply interruptions and sudden price fluctuations facing the industry. The potential for “urban mining” is massive with over 600,000 tons of potential end-of-life feedstock materials ready to support manufacturing. For these same reasons, we can offer a material cost advantage over every conventional manufacturer while shielding from market volatility and supply chain risk.

MADE IN THE USA | 08/08

An all-American solution.

Currently, greater than 90% of rare earth materials and magnet manufacturing happens in China. This puts the entire global supply chain for rare earth magnets at risk. At Noveon, our goal is to end this dependency on China. Our comprehensive magnet production process — from procurement of materials to delivery of final product — all happens right here in the United States. We proudly employ a fast-growing team of scientists, engineers and technicians and are eager to bring more jobs to America as our operations continue to expand.

Noveon is a proud American company based in Texas and the sole domestic producer of NdFeB permanent magnetic materials. All of our products are fully compliant with 10 U.S.C. §2533c©(3)© and DFARS 252.225-7052. We are the perfect partner to supply high-performance NdFeB magnets to meet the Department of Defense or other national security customer needs.

Technician in our San Marcos, Texas, facility.